PVC SG5 is a type of polyvinyl chloride (PVC) resin that is widely used in various industries. It is known for its durability, chemical resistance, and cost-effectiveness. However, it also has some disadvantages, such as its environmental impact and limited heat resistance. It is important to consider safety considerations when handling and storing PVC SG5 due to its potential toxicity. In this article, we will explore the definition, properties, manufacturing process, advantages, disadvantages, safety considerations, comparison with other PVC grades, and regulations and standards related to PVC SG5.

Key Takeaways

- PVC SG5 is a type of PVC resin that is widely used in various industries.

- It is known for its durability, chemical resistance, and cost-effectiveness.

- PVC SG5 has some disadvantages, such as its environmental impact and limited heat resistance.

- Safety considerations should be taken when handling and storing PVC SG5 due to its potential toxicity.

- There are regulations and standards in place for PVC SG5 to ensure its safe use.

What is PVC SG5?

Definition of PVC SG5

PVC SG5 is a type of PVC resin that is commonly used in various industries. It is known for its versatility and wide range of applications. PVC SG5 is a high molecular weight polymer with excellent mechanical properties and chemical resistance. It is often used in the manufacturing of pipes, fittings, profiles, and other construction materials. PVC SG5 is also used in the production of films, sheets, and cables. Its durability and cost-effectiveness make it a popular choice in many industries.

Properties of PVC SG5

PVC SG5 has several notable properties. It has good mechanical properties, including a tensile strength of about 60MPa and an impact strength of 5~10kJ/m2. Additionally, PVC SG5 exhibits excellent dielectric properties. These properties make PVC SG5 suitable for a wide range of applications.

Applications of PVC SG5

PVC SG5 is widely used in various industries due to its versatile properties. It is commonly used for the production of soft films, artificial leather, sheet, tubing, extrusions, bellows, cable protection pipes, packaging films, and more. PVC SG5 is especially suitable for applications that require durability, chemical resistance, and cost-effectiveness. Its excellent electrical insulation properties make it an ideal choice for electrical cables and wires. Additionally, PVC SG5 is often used in the construction industry for window profiles, pipes, and fittings.

PVC SG5 has a wide range of applications in the automotive sector as well. It is used for manufacturing car interiors, such as dashboards, door panels, and seat covers. The material’s ability to withstand harsh weather conditions and its resistance to chemicals makes it suitable for automotive applications. PVC SG5 is also used in the healthcare industry for medical tubing, blood bags, and IV bags due to its biocompatibility and flexibility.

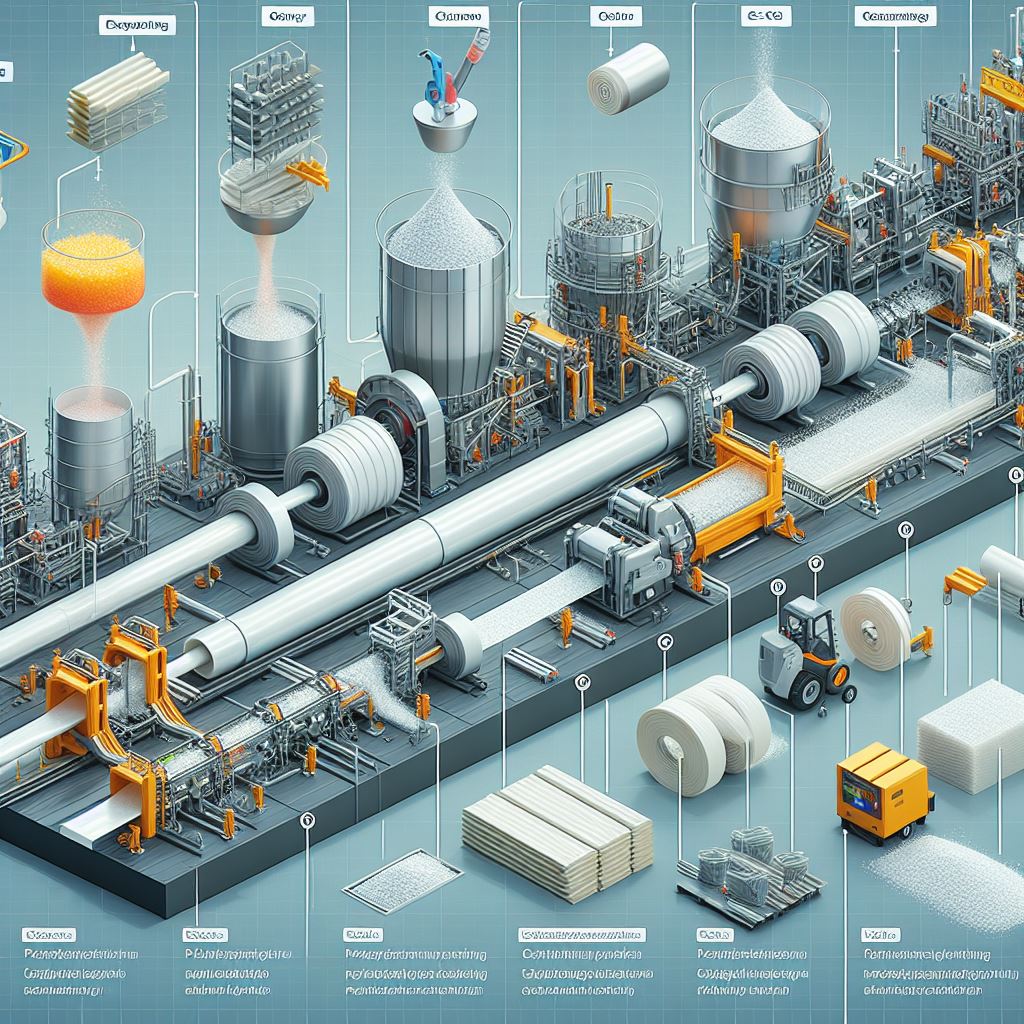

Manufacturing Process of PVC SG5

Raw Materials

PVC resin is the most widely used raw material in plastic production. It has good chemical stability, corrosion resistance, and water resistance. It can be easily molded into various shapes and sizes, making it versatile for different applications. The main components of PVC resin are vinyl chloride monomers, which undergo polymerization to form the final product. Other additives such as plasticizers, stabilizers, and fillers may also be included to enhance specific properties of the PVC SG5. These additives help improve flexibility, heat resistance, and impact strength. The quality of the raw materials used in the manufacturing process greatly affects the overall performance and durability of PVC SG5 products.

Polymerization

Polymerization is a crucial step in the manufacturing process of PVC SG5. It involves the combination of monomers to form long chains of polymer molecules. The most commonly used monomer for PVC SG5 polymerization is vinyl chloride. The polymerization reaction is typically initiated by heat or a chemical initiator.

During the polymerization process, various factors such as temperature, pressure, and catalysts are carefully controlled to ensure the desired molecular weight and properties of the PVC SG5. The polymerization reaction can be carried out in batch reactors or continuous processes.

Table: Comparison of Polymerization Methods

| Method | Description |

|---|---|

| Suspension Polymerization | Monomers are dispersed in a liquid medium, and polymerization occurs in the form of suspended particles. |

| Emulsion Polymerization | Monomers are dispersed in water with the help of emulsifiers, and polymerization occurs in the form of latex particles. |

| Bulk Polymerization | Monomers are polymerized in the absence of any solvent or dispersing medium. |

Note: The choice of polymerization method depends on the desired properties and applications of the PVC SG5.

Tip: Proper control of the polymerization process is essential to achieve PVC SG5 with consistent quality and performance.

Compounding

Compounding is an essential step in the manufacturing process of PVC SG5. It involves adding modifying components to the raw polymer to create a homogeneous mixture that is suitable for processing and meets the required performance standards. The compounding process ensures that the PVC SG5 has the desired properties, such as flexibility, impact resistance, and color stability. Various additives, such as plasticizers, stabilizers, and pigments, are incorporated during compounding to enhance the performance and appearance of the PVC SG5.

Compounding plays a crucial role in determining the final characteristics of PVC SG5 products. The type and amount of additives used during compounding can significantly affect the physical, mechanical, and chemical properties of the PVC SG5. It allows manufacturers to customize the PVC SG5 to meet specific application requirements. The compounding process also helps in achieving consistent quality and uniformity in PVC SG5 production.

Compounding is typically carried out using specialized equipment, such as high-speed mixers or twin-screw extruders. These machines ensure thorough blending of the raw materials and additives, resulting in a homogenous PVC SG5 compound. The compounded PVC SG5 can then be further processed through extrusion, injection molding, or other techniques to create a wide range of products.

Extrusion

Extrusion is a key process in the manufacturing of PVC SG5. It involves forcing the molten PVC material through a die to create a continuous profile with a specific shape and size. The extrusion process allows for the production of various PVC products, including pipes, tubes, and profiles. During extrusion, the molten PVC material is heated and pressurized, ensuring uniformity and consistency in the final product. This process is widely used in the PVC industry due to its efficiency and versatility.

Advantages of PVC SG5

Durability

PVC SG5 is known for its exceptional durability, making it a popular choice for various applications. Whether used in building and construction, medical devices, or food packaging, PVC SG5 provides a reliable and long-lasting solution. Its resistance to impact, weathering, and chemicals ensures that it can withstand harsh conditions and maintain its structural integrity over time.

In addition to its durability, PVC SG5 offers excellent dimensional stability, meaning it retains its shape and size even when exposed to temperature variations. This property makes it suitable for applications where precision and consistency are crucial.

Furthermore, PVC SG5’s low maintenance requirements contribute to its long lifespan. It is resistant to rot, corrosion, and degradation, reducing the need for frequent repairs or replacements.

Overall, the durability of PVC SG5 makes it a cost-effective choice for industries that require reliable and long-lasting materials.

Chemical Resistance

PVC SG5 exhibits excellent chemical resistance to a wide range of substances, including acids, alkalis, and solvents. It is highly resistant to corrosion and can withstand harsh environments. This makes PVC SG5 a suitable choice for applications in industries such as chemical processing, construction, and automotive. Additionally, PVC SG5’s chemical resistance contributes to its long-lasting durability and reliability.

Cost-effectiveness

One of the key advantages of PVC SG5 is its cost-effectiveness. PVC SG5 is a highly affordable material, making it a popular choice in various industries. Its low production cost and wide availability contribute to its cost-effectiveness. Additionally, PVC SG5 requires minimal maintenance, reducing long-term expenses. This makes it an attractive option for budget-conscious consumers and businesses.

Disadvantages of PVC SG5

Environmental Impact

PVC SG5 has been criticized for its environmental impact. One of the main concerns is the release of toxic chemicals during the manufacturing process and disposal of PVC products. These chemicals can have harmful effects on human health and the environment. Additionally, Polyvinyl chloride SG5 is not biodegradable, which means it can persist in the environment for a long time. This contributes to the accumulation of plastic waste and poses a threat to ecosystems.

To mitigate the environmental impact of Polyvinyl chloride SG5, it is important to consider recycling and proper disposal methods. Recycling PVC products can help reduce the demand for virgin PVC and minimize the amount of waste sent to landfills. Additionally, using alternative materials or PVC grades with lower environmental impact can be considered as a more sustainable option.

Table: Environmental Impact of PVC SG5

| Environmental Aspect | Impact |

|---|---|

| Toxic Chemicals | High |

| Biodegradability | Low |

Note: The impact level is subjective and may vary depending on specific circumstances.

Tip: When using PVC SG5, it is important to handle and dispose of it responsibly to minimize its environmental impact.

Limited Heat Resistance

One of the main limitations of PVC SG5 is its limited heat resistance. While Polyvinyl chloride SG5 has excellent durability and chemical resistance, it may not be suitable for applications that require high temperature resistance. Polyvinyl chloride SG5 has a maximum service temperature of [insert temperature]. Therefore, it is important to consider the operating temperature requirements when choosing Polyvinyl chloride SG5 for a specific application.

Safety Considerations for PVC SG5

Toxicity

Toxicity

PVC SG5 is generally considered to be a safe material for use in various applications. However, it is important to note that certain additives used in the manufacturing process of Polyvinyl chloride SG5 may pose potential health risks. These additives include plasticizers, stabilizers, and pigments. Exposure to high levels of these additives can lead to adverse health effects, such as respiratory irritation and skin sensitization.

It is recommended to follow proper safety precautions when handling and storing Polyvinyl chloride SG5. This includes wearing protective gloves, goggles, and masks to minimize direct contact with the material. Additionally, it is important to store Polyvinyl chloride SG5 in a well-ventilated area away from sources of heat and open flames.

To ensure the safe use of Polyvinyl chloride SG5, it is advisable to consult the material safety data sheet (MSDS) provided by the manufacturer for specific information on handling, storage, and disposal.

Handling and Storage

When handling and storing Polyvinyl chloride SG5, it is important to take certain precautions to ensure safety and maintain the quality of the material.

- Store Polyvinyl chloride SG5 in a cool, dry place away from direct sunlight and heat sources.

- Avoid exposure to extreme temperatures as it can cause the material to degrade.

- Keep Polyvinyl chloride SG5 away from open flames or sparks as it is combustible.

- Use appropriate personal protective equipment, such as gloves and goggles, when handling Polyvinyl chloride SG5.

- Avoid inhaling Polyvinyl chloride SG5 dust or fumes as it may cause respiratory irritation.

- If Polyvinyl chloride SG5 comes into contact with the skin, wash the affected area with soap and water.

- In case of accidental ingestion, seek medical attention immediately.

Remember to always follow the manufacturer’s instructions and consult the safety data sheet for specific handling and storage guidelines for Polyvinyl chloride SG5.

Comparison of PVC SG5 with Other PVC Grades

PVC SG3

PVC SG3 is a type of PVC grade that is commonly used in various applications. It is known for its versatility and cost-effectiveness. PVC SG3 has a lower molecular weight compared to Polyvinyl chloride SG5, which makes it more flexible and easier to process. However, it may have slightly lower mechanical properties and heat resistance.

In terms of applications, PVC SG3 is often used in the manufacturing of pipes, profiles, and films. It is also commonly used in the construction industry for window frames and siding. PVC SG3 offers good chemical resistance and durability, making it suitable for both indoor and outdoor applications.

When comparing PVC SG3 with Polyvinyl chloride SG5, it is important to consider the specific requirements of the intended application. PVC SG3 may be more suitable for applications that require flexibility and ease of processing, while Polyvinyl chloride SG5 may be preferred for applications that require higher mechanical strength and heat resistance.

Note: The information provided in this section is for general reference only and should not be considered professional advice.

PVC SG8

PVC SG8 is another grade of PVC resin that is commonly used in various applications. It shares many similarities with Polyvinyl chloride SG5, but there are some key differences to consider.

One important aspect to note is the formula of PVC SG8, which is [CH2-Chcl]N. This formula represents the chemical structure of PVC resin and is essential in understanding its properties and behavior.

PVC SG8 has a similar appearance to Polyvinyl chloride SG5, as it is also a white powder. However, it may have different characteristics and performance attributes that make it suitable for specific applications.

When comparing PVC SG8 with Polyvinyl chloride SG5, it is important to consider factors such as durability, chemical resistance, and cost-effectiveness. These properties can vary between the two grades and may influence the choice of PVC resin for a particular application.

Overall, Polyvinyl chloride SG8 is a versatile grade of PVC resin with unique properties and advantages. It is widely used in various industries and applications, providing a reliable and cost-effective solution for different needs.

Regulations and Standards for PVC SG5

International Standards

Polyvinyl chloride SG5 is manufactured according to various international standards to ensure its quality and performance. These standards provide guidelines for the composition, physical properties, and testing methods of Polyvinyl chloride SG5. Some commonly followed international standards for Polyvinyl chloride SG5 include ISO 9001:2015, ASTM D1784, and EN 1329. These standards help in maintaining the consistency and compatibility of Polyvinyl chloride SG5 across different industries and applications.

Regional Regulations

Regional regulations play a crucial role in the use and production of Polyvinyl chloride SG5. These regulations vary from country to country and are designed to ensure the safe and responsible handling of Polyvinyl chloride SG5. They cover aspects such as manufacturing standards, environmental impact, and worker safety. Compliance with regional regulations is essential to maintain the integrity of Polyvinyl chloride SG5 products and to protect the environment and human health. Manufacturers, distributors, and users of Polyvinyl chloride SG5 need to stay updated with the latest regional regulations to ensure compliance and mitigate any potential risks or liabilities.

Conclusion

In conclusion, Polyvinyl chloride SG5 is a versatile and widely used material in various industries. Its durability and cost-effectiveness make it a popular choice for applications such as construction, packaging, and automotive. However, it is important to consider the environmental impact of Polyvinyl chloride SG5 and explore sustainable alternatives. Overall, understanding the properties and uses of Polyvinyl chloride SG5 is essential for making informed decisions in the modern world.

Frequently Asked Questions

What is PVC SG5?

Polyvinyl chloride SG5 is a type of polyvinyl chloride (PVC) resin with specific properties and characteristics. It is commonly used in various applications due to its durability, chemical resistance, and cost-effectiveness.

What are the properties of PVC SG5?

Polyvinyl chloride SG5 has good mechanical properties, including high tensile strength and impact resistance. It is also resistant to chemicals, weathering, and UV radiation. Additionally, it has good electrical insulation properties.

What are the applications of PVC SG5?

Polyvinyl chloride SG5 is used in a wide range of applications, including the manufacturing of pipes, fittings, profiles, cables, films, sheets, and various plastic products. It is also used in the construction, automotive, electrical, and packaging industries.

What is the manufacturing process of PVC SG5?

The manufacturing process of Polyvinyl chloride SG5 involves several steps. It starts with the selection and preparation of raw materials, followed by polymerization to produce PVC resin. The resin is then compounded with additives and stabilizers to enhance its properties. Finally, the compounded Polyvinyl chloride SG5 is extruded into the desired shape or form.

What are the advantages of PVC SG5?

Polyvinyl chloride SG5 offers several advantages. It is highly durable and can withstand harsh environmental conditions. It is also resistant to chemicals, making it suitable for applications where chemical resistance is required. Additionally, Polyvinyl chloride SG5 is cost-effective compared to other materials.

What are the disadvantages of PVC SG5?

Despite its many advantages, Polyvinyl chloride SG5 has some disadvantages. One of the main concerns is its environmental impact, as PVC production involves the release of toxic chemicals. Polyvinyl chloride SG5 also has limited heat resistance, which may restrict its use in high-temperature applications.

Chlorinated Polyvinyl Chloride Resin: Benefits of using in Manufacturing