Introduction

You have ever wondered about the secret behind versatile plastic products that you encounter in your everyday life? From the ergonomic chairs, and car parts, to the packaging materials? Meet Thermo Plastic Resin, a powerful substance that shapes our world.

Defining Thermo Plastic Resin

Thermo Plastic Resin, also known as thermoplastics, originates from polymer resins, constituting a distinct category of plastics. What sets these plastics apart is their flexibility and pliability when subjected to heat.

Understanding the Basics of Thermo Plastic Resin

The very essence of any thermoplastic lies in its structure. Comprised of long polymer chains, these substances soften when heated, enabling their seamless molding for myriad uses. Cool them, and they toughen back into a solid structure, hence the term “thermo”-plastic.

Key Properties of Thermo Plastic Resin

Thermoplastics possess several key properties that significantly influence their broad application. High durability, resistance to wear and tear, strength, and solid structure are some of them. Also, their capacity for repeated melting and molding makes them uber-reusable.

Production Process of Thermo Plastic Resin

Manufacturers produce thermoplastics through polymerization. In this process, monomers or substance units bond together to form a larger structure called a polymer, creating plastic resin. Injecting heat into the mix enables the manipulation of thermoplastics into desired forms.

Types of Thermo Plastic Resin

Thermoplastics are a diverse group with several types, each providing a unique blend of qualities. Some common types include Polyethylene (PET), Polyvinyl Chloride (PVC), Polypropylene (PP), and many others.

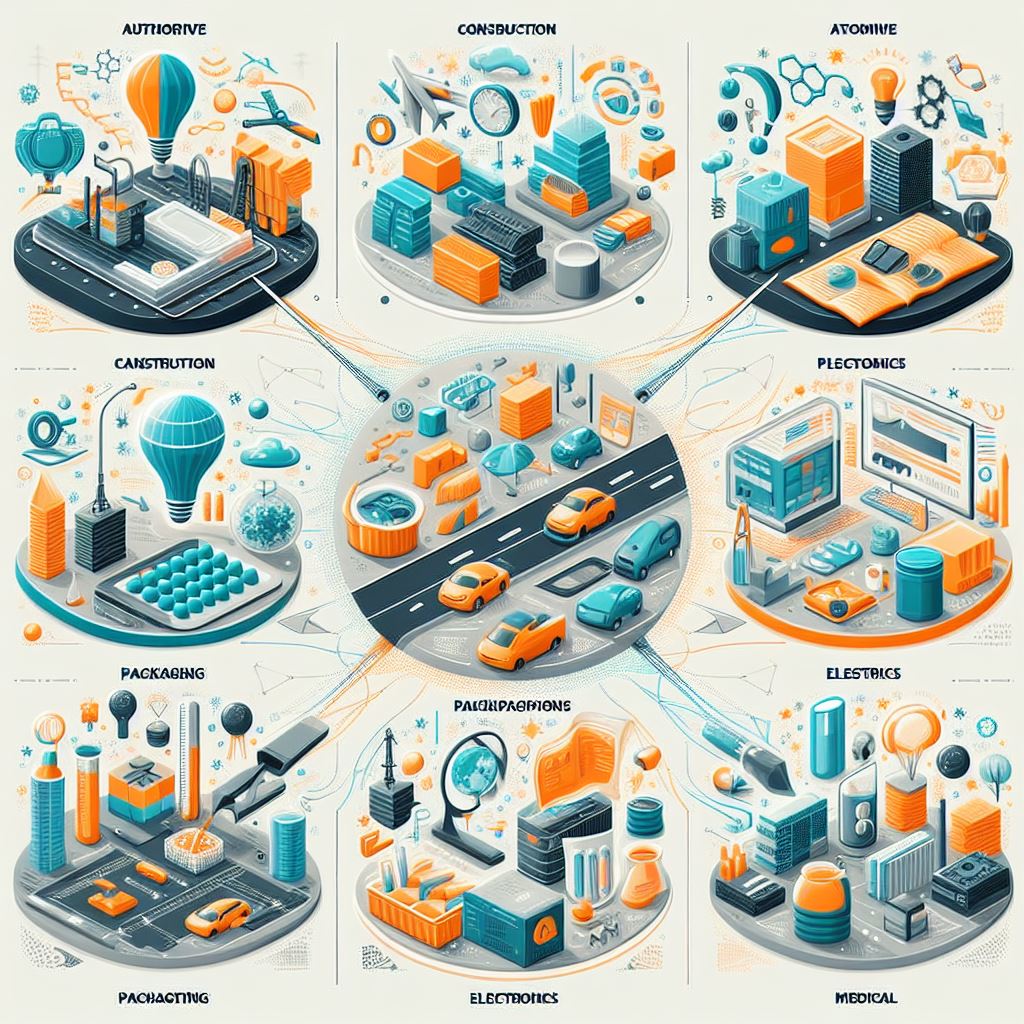

The Role of Thermo Plastic Resin in Different Industries

- The Automotive Industry:

Did you know that about 50% of your car’s manufacturing involves thermoplastics? From the interior fixtures, insulation, fuel systems to bumpers, thermoplastics play an integral role in vehicles today.

- The Packaging Industry:

Imagine a world without packaging. Quite chaotic, right? Thermoplastic resins are fundamental to this industry, creating ideal packaging materials from bags, bottles, and jars, to films.

- Aerospace Industry:

With their weight-saving ability, thermoplastics are increasingly used in the aerospace industry. They offer safety, efficiency, and durability, qualities indispensable in aircraft construction.

Benefits of Using ThermoPlastic Resin

Thermoplastics retain their intrinsic properties even when melted and reshaped repeatedly. They are also highly durable and versatile, offering endless application possibilities. Thermoplastics also offer cost-effectiveness due to their recyclability.

Environmental Impact of ThermoPlastic Resin

While thermoplastics are recyclable, incorrect disposal can harm our environment by cluttering and polluting it. Therefore, concerted efforts are needed to improve recycling practices.

The Economic Impact of ThermoPlastic Resin

Thermoplastics have a substantial effect on economies worldwide. By fueling many industries, they create jobs, innovate technology, and provide economic stability.

Innovations in ThermoPlastic Resin

The advancements in science have brought forth innovations in producing greener and more efficient thermoplastics. These efforts are designed to improve their environmental footprint, quality, and functionality.

The Future of ThermoPlastic Resin

Thermoplastics stand tall in our future vision. Rising environmental concerns and the quest for sustainability will motivate more innovation, transforming society and economy alike.

Conclusion

Undeniably, the powerful impact of Thermo Plastic Resin can’t be overlooked. It’s interwoven in the fabric of our lives, our industries, and our future. As we journey ahead, the importance of thermoplastics will only amplify, evolving in tandem with our needs.

FAQs

- What’s the main difference between thermoplastics and other plastics?

Thermoplastics can be reshaped multiple times without their properties being affected, unlike other plastics.

- Why are thermoplastics popular in many industries?

Their high durability, versatility, weight-saving ability, and cost-effectiveness contribute to their popularity in various industries.

- Are all thermoplastics environmentally friendly?

While thermoplastics are recyclable, incorrect disposal can harm the environment. Therefore, improved recycling practices are essential.

- How does Thermo Plastic Resin contribute to the economy?

Thermoplastics fuel many industries, create jobs, innovate technologies, and contribute to economic stability.

- What does the future hold for Thermo Plastic Resin?

The future of thermoplastics lies in innovation to improve their environmental footprint, quality, and functionality.

Pingback: Titanium Dioxide for Soap: Innovative and Affordable Approach - Safe Climber Overseas Pvt. Ltd.