Introduction

Titanium Dioxide Powder, also known as TiO2, is one of the most versatile and widely used materials in various industries today. This comprehensive guide will explore everything you need to know about this remarkable compound, from its basic properties to its diverse applications and environmental considerations.

What is Titanium Dioxide Powder?

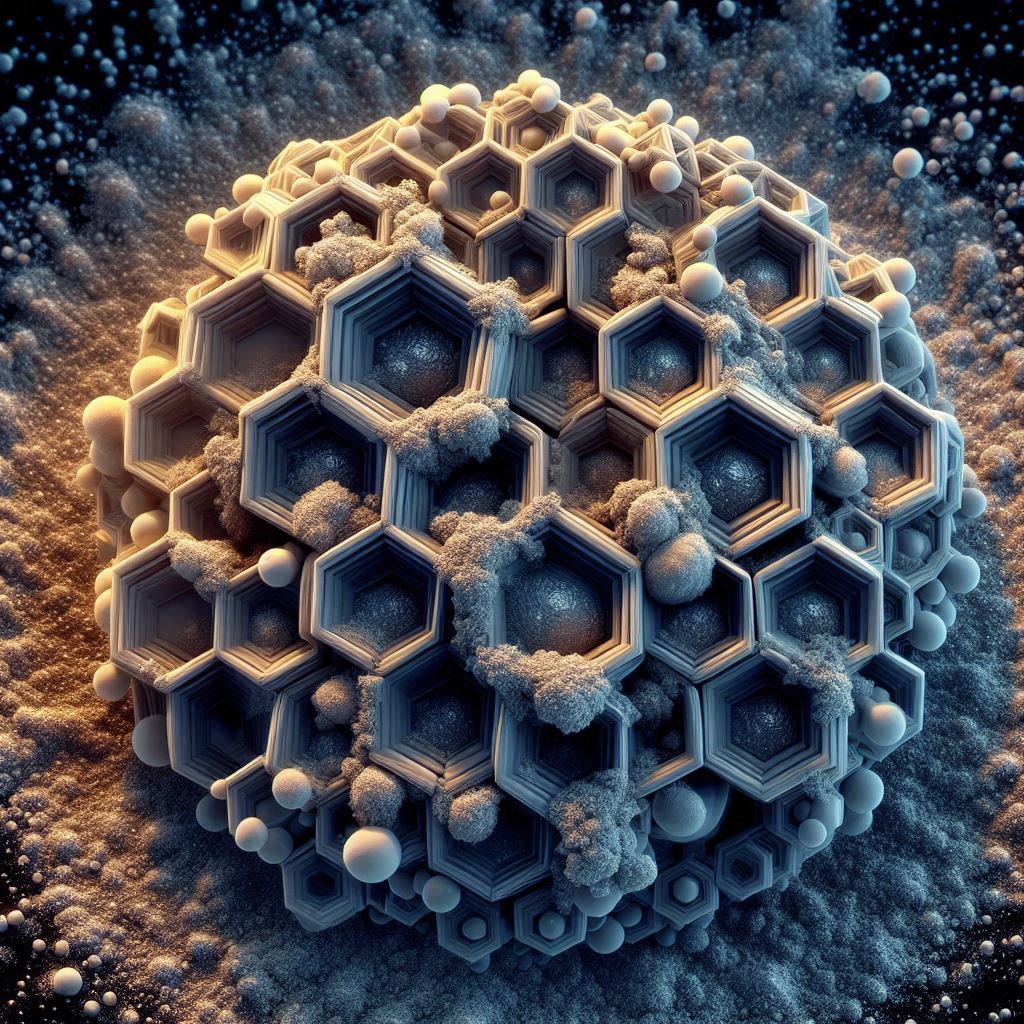

Titanium Dioxide Powder is a naturally occurring oxide of titanium with the chemical formula TiO2. This inorganic compound appears as a fine, white powder and is known for its excellent opacity, brightness, and UV-resistant properties. The significance of TiO2 Powder in modern industry cannot be overstated, as it plays a crucial role in numerous applications across various sectors.

Key Characteristics of Titanium Dioxide Powder:

| Property | Description |

|---|---|

| Appearance | Fine white powder |

| Chemical Formula | TiO2 |

| Molecular Weight | 79.87 g/mol |

| Density | 4.23 g/cm³ |

| Melting Point | 1,843°C (3,349°F) |

| Boiling Point | 2,972°C (5,382°F) |

| Solubility | Insoluble in water |

| Refractive Index | 2.49-2.61 |

Chemical Properties and Composition

Titanium Dioxide Powder consists of titanium and oxygen atoms arranged in a specific crystalline structure. The compound exists in three main crystalline forms:

- Rutile

- Anatase

- Brookite

Crystalline Forms Comparison:

| Form | Structure | Stability | Common Applications |

|---|---|---|---|

| Rutile | Tetragonal | Most stable | Paints, plastics, cosmetics |

| Anatase | Tetragonal | Less stable | Photocatalysts, self-cleaning surfaces |

| Brookite | Orthorhombic | Least stable | Research purposes |

Manufacturing Process

The production of TiO2 Powder involves two main processes:

1. Sulfate Process:

- Raw material: Ilmenite ore

- Treatment with sulfuric acid

- Purification and calcination

- Final product processing

2. Chloride Process:

- Raw material: Rutile ore

- Chlorination

- Purification

- Oxidation

- Surface treatment

Process Comparison Table:

| Aspect | Sulfate Process | Chloride Process |

|---|---|---|

| Raw Materials | Ilmenite | Rutile |

| Environmental Impact | Higher | Lower |

| Cost | Lower | Higher |

| Product Quality | Good | Excellent |

| Production Efficiency | Moderate | High |

Types of Titanium Dioxide Powder

Different grades and types of Titanium Dioxide Powder are available for various applications:

Classification Table:

| Grade | Particle Size | Primary Use | Key Features |

|---|---|---|---|

| Food Grade | 0.2-0.3 μm | Food coloring | High purity, safe for consumption |

| Cosmetic Grade | 0.1-0.2 μm | Cosmetics, sunscreens | UV protection, skin-safe |

| Industrial Grade | 0.3-0.4 μm | Paints, plastics | High durability, good coverage |

| Photocatalytic Grade | 0.02-0.1 μm | Self-cleaning surfaces | Enhanced photocatalytic activity |

Applications and Uses

TiO2 Powder finds application in numerous industries:

1. Paints and Coatings

- White pigment

- UV protection

- Durability enhancement

- Weather resistance

2. Cosmetics and Personal Care

- Sunscreens

- Makeup products

- Toothpaste

- Skincare products

3. Food Industry

- Food coloring (E171)

- Coating for candies

- Brightening agent

4. Industrial Applications

- Plastics

- Paper

- Textiles

- Ceramics

Application Distribution Table:

| Industry Sector | Market Share (%) | Annual Growth Rate (%) |

|---|---|---|

| Paints & Coatings | 55-60 | 4.5 |

| Plastics | 25-30 | 3.8 |

| Paper | 5-7 | 2.5 |

| Cosmetics | 4-6 | 5.2 |

| Others | 3-5 | 3.0 |

Safety and Regulations

Regulatory Standards for Titanium Dioxide Powder:

| Region | Regulatory Body | Key Regulations |

|---|---|---|

| USA | FDA | 21 CFR 73.575 |

| EU | EFSA | E171 |

| Japan | MHLW | Standards for Use |

| China | GB | GB 25576-2010 |

Safety Measures Table:

| Aspect | Guidelines | Protective Measures |

|---|---|---|

| Handling | Use in well-ventilated areas | Wear protective equipment |

| Storage | Keep in sealed containers | Away from moisture |

| Exposure Limits | TWA: 10 mg/m³ | Regular monitoring |

| First Aid | Immediate washing | Medical attention if needed |

Environmental Impact

Environmental Considerations Table:

| Aspect | Impact | Mitigation Measures |

|---|---|---|

| Water Systems | Moderate | Proper filtration systems |

| Air Quality | Low | Dust control measures |

| Soil | Minimal | Proper disposal methods |

| Biodegradability | Non-biodegradable | Recycling programs |

Market Overview

Global Market Statistics:

| Region | Market Share (%) | Growth Rate (%) |

|---|---|---|

| Asia Pacific | 45 | 5.8 |

| North America | 25 | 4.2 |

| Europe | 20 | 3.9 |

| Rest of World | 10 | 4.5 |

Frequently Asked Questions (FAQs)

- What is TiO2 Powder primarily used for?

- Titanium Dioxide Powder is primarily used as a white pigment in paints, coatings, plastics, paper, foods, cosmetics, and other applications requiring brightness and opacity.

- Is TiO2 Powder safe for use in cosmetics?

- Yes, when properly formulated and used as directed, Titanium Dioxide Powder is considered safe for cosmetic use. It’s approved by regulatory bodies worldwide for use in cosmetics and sunscreens.

- How is TiO2 Powder manufactured?

- Titanium Dioxide Powder is manufactured through either the sulfate process or the chloride process, using various titanium-containing ores as raw materials.

- What makes TiO2 Powder an effective UV blocker?

- Titanium Dioxide Powder has excellent UV-absorbing properties due to its high refractive index and ability to scatter and absorb UV radiation.

- Can TiO2 Powder be harmful to the environment?

- While Titanium Dioxide Powder is generally stable and inert, proper handling and disposal practices should be followed to minimize environmental impact.

- What are the different grades of TiO2 Powder?

- The main grades include food grade, cosmetic grade, industrial grade, and photocatalytic grade, each designed for specific applications.

- How should TiO2 Powder be stored?

- Store in a cool, dry place in sealed containers away from moisture and direct sunlight.

- What are the alternatives to TiO2 Powder?

- Alternatives include zinc oxide, iron oxides, and various organic pigments, though they may not match all properties of Titanium Dioxide Powder.

- Is Titanium Dioxide Powder regulated in food products?

- Yes, it’s regulated as food additive E171 in the EU and is approved by the FDA in the US, with specific limitations and requirements.

- What is the future outlook for Titanium Dioxide Powder?

- The market for Titanium Dioxide Powder is expected to grow steadily due to increasing demand in various industries and technological advancements.

Conclusion

Titanium Dioxide Powder remains an indispensable material across numerous industries, from paints and coatings to cosmetics and food products. Its versatility, stability, and unique properties make it a crucial component in many applications. As research continues and new applications emerge, the importance of Titanium Dioxide Powder in various industries is likely to grow further.

Understanding the properties, applications, and proper handling of Titanium Dioxide Powder is essential for professionals working in related industries. With ongoing developments in manufacturing processes and applications, Titanium Dioxide Powder will continue to play a vital role in various sectors while adhering to safety and environmental regulations.

Key Takeaways:

- Versatile material with numerous applications

- Available in different grades for specific uses

- Regulated for safety in various applications

- Growing market with positive future outlook

- Important considerations for environmental impact

- Continuous research and development for new applications

The future of Titanium Dioxide Powder looks promising, with new applications and improved manufacturing processes being developed regularly. As industries continue to evolve, the demand for this versatile compound is expected to grow, making it an essential material for years to come.

TiO2 Treatment: Unveiling Its Role In Sustainable Technology

TiO2 Treatment: Unveiling Its Role In Sustainable Technology

Pingback: E171 And Cancer: The Alarming Research You Need To Know - Safe Climber Overseas Pvt. Ltd.