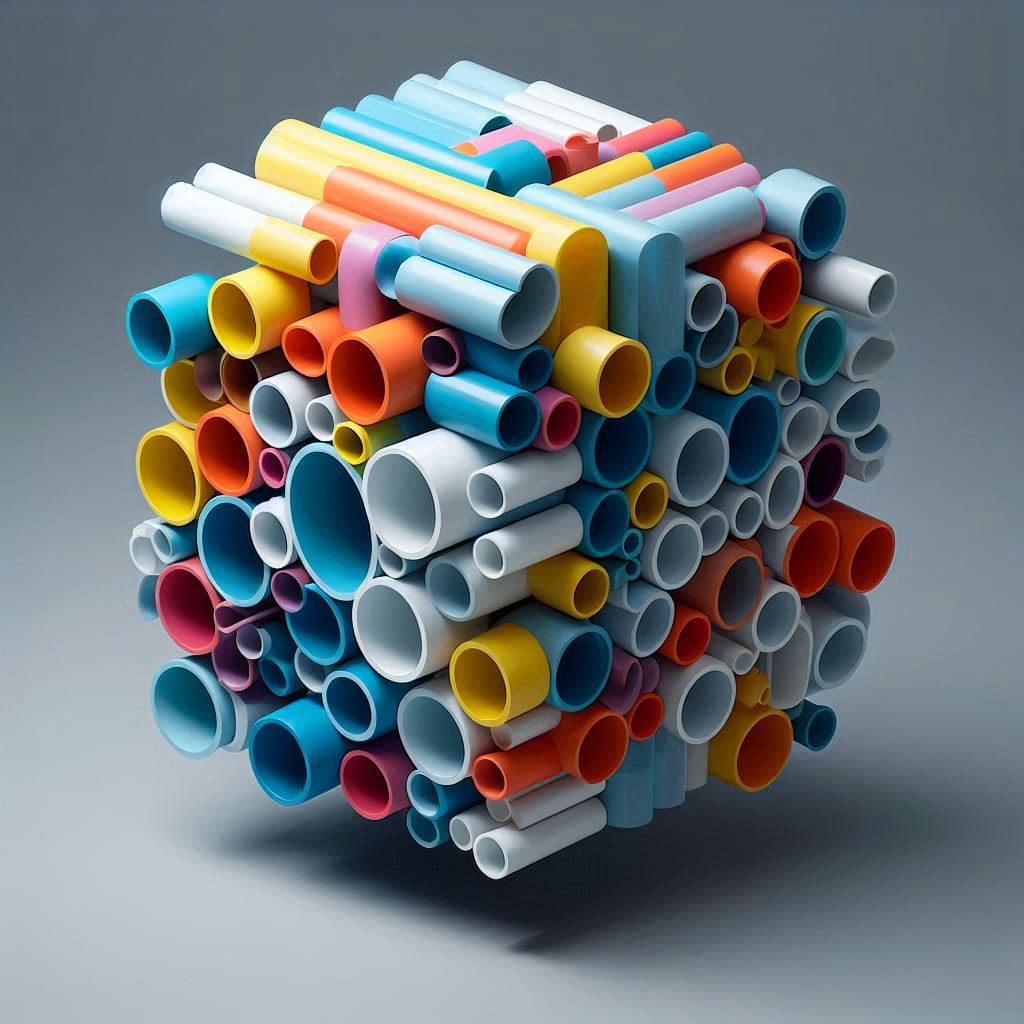

Introduction to 1 1/2 Inch PVC Pipe

1 1 2 PVC Pipe: Divers into the world of construction and plumbing frequently encounter the 1 1/2 inch PVC pipe as a standout choice. Its remarkable adaptability and durability explain its popularity, not just a fluke. This comprehensive guide is designed to walk you through everything from what PVC is to its uses, how it’s made, and even some fun DIY projects.

What is PVC?

Definition and properties

PVC, or polyvinyl chloride, is a plastic widely renowned for its strength, light weight, and resistance to water and corrosion. This makes it ideal not only in plumbing but in countless other uses where reliability is key.

Comparison with other piping materials

PVC pipes often replace materials like copper and galvanized steel due to several advantages. They are less susceptible to corrosion, easier to install, and significantly cheaper, making them a smart choice for budget-conscious projects.

Specifics of 1 1 2 pvc pipe

Dimensions and measurements

The “1 1/2 inch” measurement refers to the nominal inside diameter, with wall thickness varying by the schedule or wall class, affecting flow rates and pressure handling.

Common uses in plumbing and construction

This size pipe is frequently used in residential plumbing for draining and vent stacking since it aligns well with the typical output size of various home fixtures.

Advantages of Using PVC Pipes

Cost-effectiveness

There’s a notable difference in cost if you’re deciding between PVC and metals. For tight budgets, PVC provides a robust option without the wallet bite.

Durability and longevity

One of the greatest advantages of PVC is its ability to stand the test of time without significant degradation.

Maintenance and corrosion resistance

In environments where metal pipes might rust or corrode, PVC excels by maintaining integrity over long periods, even in harsh chemical or saline exposures.

Manufacturing and Standards

How 1 1 2 pvc pipe are Made

Raw materials used

The primary ingredient in PVC pipes is polyvinyl chloride, combined with stabilizers and lubricants to refine the properties of the final product.

The manufacturing process

Manufacturing PVC involves extrusion of the heated materials through a die, which shapes the molten plastic into the stable form of a pipe.

Quality control measures

Close monitoring during manufacturing ensures that the pipes meet established thickness, diameter, and strength standards.

Standards and Certifications

International standards compliance (e.g., ASTM, ISO)

PVC pipes commonly adhere to strict standards like ASTM D1785 and ISO 9001 to guarantee reliability and safety.

Significance of certifications in quality assurance

These certifications help reassure the quality and compliance of plumbing installations, crucial for both safety and functionality.

Environmental Impact

Sustainability in production

Recent advancements aim to reduce the ecological footprint of PVC production by optimizing and recycling processes.

Recyclability and environmental considerations

PVC is recyclable and strategies are continually developing to enhance its lifecycle management and reuse.

Trends in eco-friendly manufacturing practices

Manufacturers are increasingly leaning into more sustainable practices, including the use of non-toxic and recycled materials.

Installation Techniques: 1 1 2 pvc pipe

Tools and Preparation

Essential tools for working with PVC

You’ll need basic tools like cutters, sandpaper for burrs, and specific PVC glue.

Pre-installation preparation steps

Measure twice, cut once! Ensuring precise measurements beforehand saves a lot of hassle later.

Step-by-Step Installation Guide: 1 1 2 pvc pipe

Cutting and measuring accurately

Always ensure you’re working with the exact lengths to avoid pressure issues and possible leaks.

Joining techniques: Gluing, threading, etc.

Gluing is the most common method, providing a watertight seal. Some connections might require threading based on pressure needs.

Troubleshooting Common Installation Issues: 1 1 2 pvc pipe

Solutions to common problems

Facing a leak? Make sure all fittings are secure, and seals are correctly applied.

Tips for ensuring a leak-free setup

Regular checks during installation can prevent future headaches.

Maintenance and Repairs: 1 1 2 pvc pipe

Routine Maintenance Tips

Inspection schedules

Regularly inspecting your PVC plumbing plays a crucial part in prolonged infrastructure health.

Cleaning and upkeep

Simple cleaning with soapy water helps maintain the pipes’ condition and functionality.

Common Issues and Fixes: 1 1 2 pvc pipe

How to deal with cracks and leaks

Small cracks can be patched, but larger ones might require section replacement.

When to repair vs. when to replace

If repairs become too frequent, it might be more cost-effective to consider replacing the problematic sections.

Advanced Maintenance Techniques: 1 1 2 pvc pipe

Techniques like pressure testing

This can identify vulnerability points before they turn into major issues.

Long-term preservation methods

Proper installation and occasional resealing can extend the life significantly.

Innovative Uses and Projects

Beyond Plumbing: Unique Uses of 1 1 2 pvc pipe

Creative minds have repurposed PVC into furniture, garden structures, and even art installations.

Creative projects and DIY ideas

Imagine constructing a frame for a small greenhouse or creating custom shelving units.

Case Studies: 1 1 2 pvc pipe

Real-life examples of innovative uses

From hydroponic gardens to designer room dividers, the adaptability of PVC pipes inspires incredible projects.

Impact of these projects

These ventures not only recycle materials but also foster inventiveness and personal expression.

Future Trends in PVC Applications

Technological advancements

As material science evolves, anticipate seeing PVC that’s even more durable and eco-friendly.

Predictions for new fields of application

Expect breakthroughs where PVC might be used in high-tech industries like aerospace for non-critical components.

Conclusion

Recap of Key Points

We’ve traversed through what 1 1/2 inch PVC pipes are all about, their benefits, and the broader impacts they have on industries and environments alike.

Final Thoughts on the Versatility and Importance of 1 1/2 Inch PVC Pipes

Their resilience, affordability, and flexibility make them indispensable in modern construction and beyond.

FAQs

What is the life expectancy of a 1 1/2 inch PVC pipe?

Typically, PVC pipes can last upwards of 50 to 70 years, depending on use and environmental conditions.

Can 1 1/2 inch PVC pipes be used for hot water systems?

PVC pipes are generally not recommended for hot water above 140°F as the heat can degrade the material.

How does UV exposure affect 1 1/2 inch PVC pipes?

Prolonged UV exposure can lead to brittleness, although exterior-grade PVC is treated to resist this.

What are the best practices for cutting 1 1/2 inch PVC pipes?

Use a dedicated PVC cutter for the cleanest, most even cuts.

Are there alternative materials recommended over PVC for specific applications?

In situations requiring high temperatures or pressures, materials like CPVC or metal might be more suitable.

Soft Vinyl Chloride: Unveiling The Secrets Of PVC